Why leaders must pivot technology investment from purely operational systems to project productivity tools to design and build the future.

The Silent Shift Reshaping Business

Pull up your company’s strategic roadmap for the next three years. Chances are, it’s not about producing the same component 1% faster or trimming pennies from supply chain costs. Instead, you’ll find ambitious initiatives: launching next-generation electric vehicles, developing more efficient jet engines, engineering lighter aerospace composites, or releasing new lines of smart, connected electronics.

Your company’s future hinges on a portfolio of complex, groundbreaking projects.

This isn’t a passing trend — it’s a fundamental economic transformation. Antonio Nieto-Rodriguez, an influential voice in strategic management, calls this the Project Economy: an era where work revolves around discrete projects rather than repetitive operational tasks.

Here’s the paradox: while your corporate strategy has already embraced this project-driven reality, your budgets remain stubbornly anchored to the factory floor, optimizing systems that build yesterday’s products. To win the next decade, leaders must urgently rebalance investments away from running the factory and toward changing the product — by adopting tools that supercharge project productivity.

Understanding the Project Economy

The Project Economy marks a decisive shift from repetition to creation.

- The Operations Economy (The Past): Think of the familiar rhythm of the assembly line — Six Sigma quality control, optimized supply chains, just-in-time inventory management. The goal was simple: do the same things better, faster, cheaper.

- The Project Economy (The Future): This is the design sprint for a revolutionary automotive chassis, the R&D journey for a breakthrough medical device, or the intricate certification process for new railway technology. The goal has evolved: do new things successfully.

As Nieto-Rodriguez argues, projects are no longer confined to R&D departments. For modern manufacturers, projects are the business.

Four Forces Driving the Shift

This transformation isn’t theoretical — it’s being driven by converging market forces:

- The Smart Factory Revolution: Every IoT sensor embedded in a product, every AI algorithm deployed for predictive maintenance, and every digital twin built for virtual testing represents a project. IDC projects that digital transformation investment will approach $7.4 trillion, with every dollar deployed through project-based work.

- ESG and Regulatory Pressure: Sustainability is no longer optional. Designing for disassembly, incorporating recycled materials, and meeting stringent emissions standards are massive engineering undertakings that define brand reputation and regulatory compliance. A recent PwC survey found that nearly 50% of CEOs are increasing ESG investment — all project-based work.

- Accelerating Product Cycles: Automotive model cycles have compressed from seven years to under four. Consumer electronics refresh annually. If you can’t manage the project of bringing new products to market faster than competitors, you’re already losing ground.

- The Battle for Talent: Top engineers and designers don’t want to maintain legacy product lines — they want to build the future. A project-based culture focused on innovation has become essential for attracting and retaining the talent you need to compete.

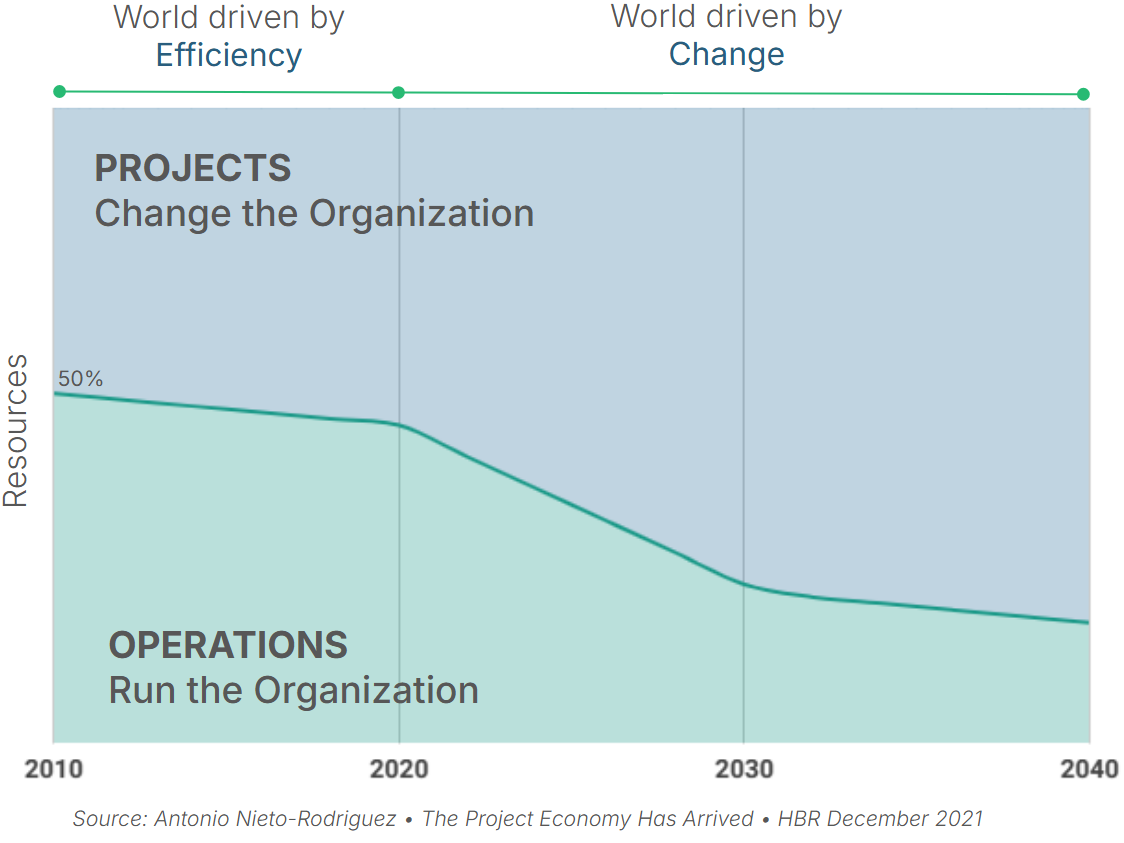

The Tipping Point: A 10-Year Horizon

The trajectory is clear: within the next decade, the majority of your organization’s resources, talent, and leadership attention will shift from daily operations to strategic projects. Your company’s value will be determined less by operational efficiency and more by project execution prowess.

The sobering reality? Companies optimized purely for operational excellence risk becoming perfectly efficient at manufacturing obsolete products. The winners will be those who master the art of the project.

The Great Rebalancing - Resource Allocation Shift

The projected shift in resource allocation from running the business (Operations) to

changing the business (Projects) over the next decade.

The Strategic Blind Spot

For decades, Enterprise Resource Planning (ERP) systems have dominated manufacturing IT budgets. Companies have invested fortunes implementing and customizing these platforms to manage inventory, production schedules, and factory floor operations through Manufacturing Execution Systems (MES). While essential, these systems serve one primary purpose: running the business as it exists today.

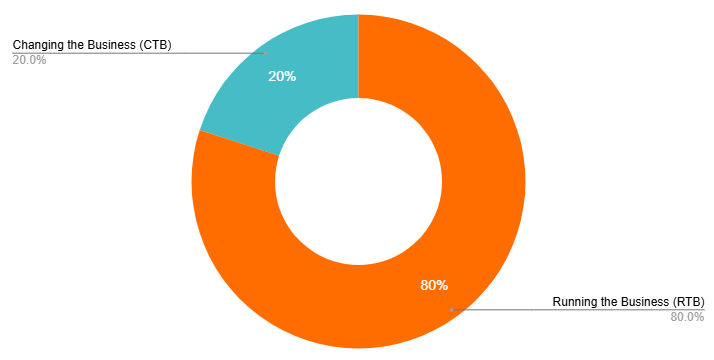

This operational focus creates a well-documented imbalance. IT spending typically falls into two categories: Run the Business (RTB) for daily operations, and Change the Business (CTB) for transformational projects.

The data reveals a stark reality: across industries, large companies allocate over 80% of IT budgets just to keeping the lights on.

The IT Budget - The Current Imbalance

A typical IT budget, heavily skewed towards operational systems over tools that drive project-based innovation.

This operational bias creates a barrier to innovation and raises a critical question: if your future depends on launching better products faster, what percentage of your technology spend actually accelerates product development?

For most companies, the answer exposes a dangerous disconnect. Millions flow into operational ERPs while engineering teams manage complex project dependencies in spreadsheets, struggling to collaborate across mechanical, electrical, and software disciplines.

This inefficiency is costly. According to the Project Management Institute, 11.4% of every dollar invested in projects is wasted due to poor execution — your R&D budget evaporating before it creates value.

The Compounding Cost of Inaction

This budget imbalance isn’t conservative strategy — it’s a recipe for stagnation with escalating costs.

The Productivity Paradox

A landmark McKinsey study revealed that higher IT spending doesn’t correlate with higher productivity. The reason? Increased investment gets absorbed by the mounting cost and complexity of maintaining bloated legacy systems — the classic RTB trap. When most technology spending props up inefficient infrastructure, returns diminish rapidly.

The Technical Debt Anchor

The single greatest driver of bloated RTB budgets is technical debt — the cost of rework from choosing easy short-term solutions over better long-term ones. This is a crippling issue, with analysis showing that up to 40% of an entire IT budget can be consumed by mitigating the fallout from past architectural shortcuts. This debt functions as a tax on all future innovation.

The Vicious Cycle

This creates a self-reinforcing trap: high legacy system costs consume the budget, convincing leadership that modernization is unaffordable. Meanwhile, those legacy systems become progressively more expensive and fragile, tightening the grip.

Five Strategies for the Project Economy

Thriving in this era requires bold strategic shifts in mindset and resource allocation.

Reframe IT as Value Creation

Stop treating IT as a cost center. Shift the conversation from “reducing IT cost per revenue dollar” to “increasing revenue generated per IT dollar invested.” This elevates discussions from line-item expenses to strategic returns.

Fund Modernization to Liberate Resources

The most effective way to free capital for innovation is making targeted CTB investments in modernization and automation that permanently reduce RTB costs. Position cloud migrations or application consolidation not as expenses, but as investments with clear ROI: “A $5M investment will permanently reduce annual operating costs by $3M starting year three.”

Prioritize Project Productivity Tools

Your engineering teams can’t build the future while battling disconnected systems and spreadsheets. Investing in modern project technology stacks — integrated Product Lifecycle Management (PLM) and Project Portfolio Management (PPM) platforms — isn’t an operational expense. It’s a strategic investment yielding faster time-to-market and higher new product introduction success rates.

Build Project Management Capability

Tools alone won’t deliver transformation. As Gartner notes, project management is increasingly everyone’s responsibility. Cultivate a culture where project management becomes a core competency for lead engineers and product managers, not just a specialized department function.

Make the Case with Data

Quantify the opportunity cost of inaction. Calculate what 11.4% waste on your annual R&D budget represents in absolute dollars. Model the revenue impact of reducing time-to-market by even 10%. These numbers make the case for rebalancing IT investment.

Lead the Transformation

The Project Economy isn’t a future scenario—it’s today’s reality in manufacturing. The assembly line’s roar represents your present; the collaborative energy of project teams designing breakthrough products represents your future.

The accelerating wave of AI-driven innovation will only intensify this shift. Organizations that fail to rebalance budgets now will find themselves unable to capitalize on new opportunities, cementing their position as industry laggards.

Stop perfecting yesterday’s operational machinery. It’s time to invest in the project engine that will build tomorrow.

The question isn’t whether this shift will happen. It’s whether your organization will lead it or be left behind.